CHEMICAL HANDLING

Supa BatchPro

The Supa Batch Pro Batching System will streamline your on-farm chemical mixing, particularly where powders and granules are concerned.

With the option of an 800lt or 12oolt capacity tank.

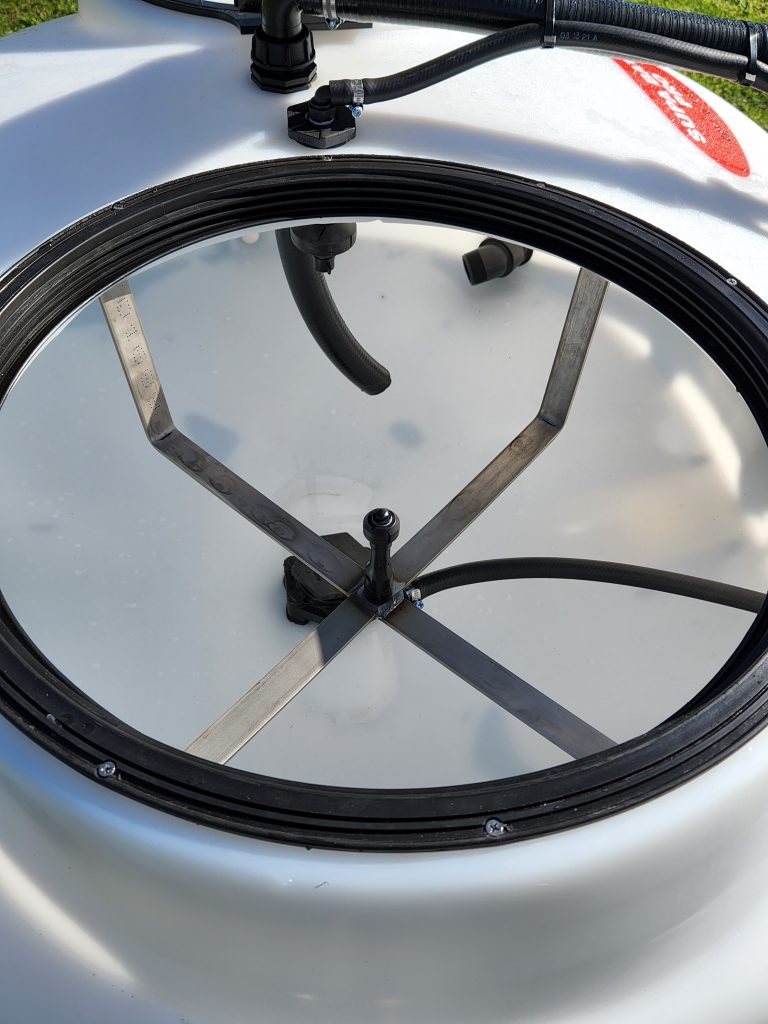

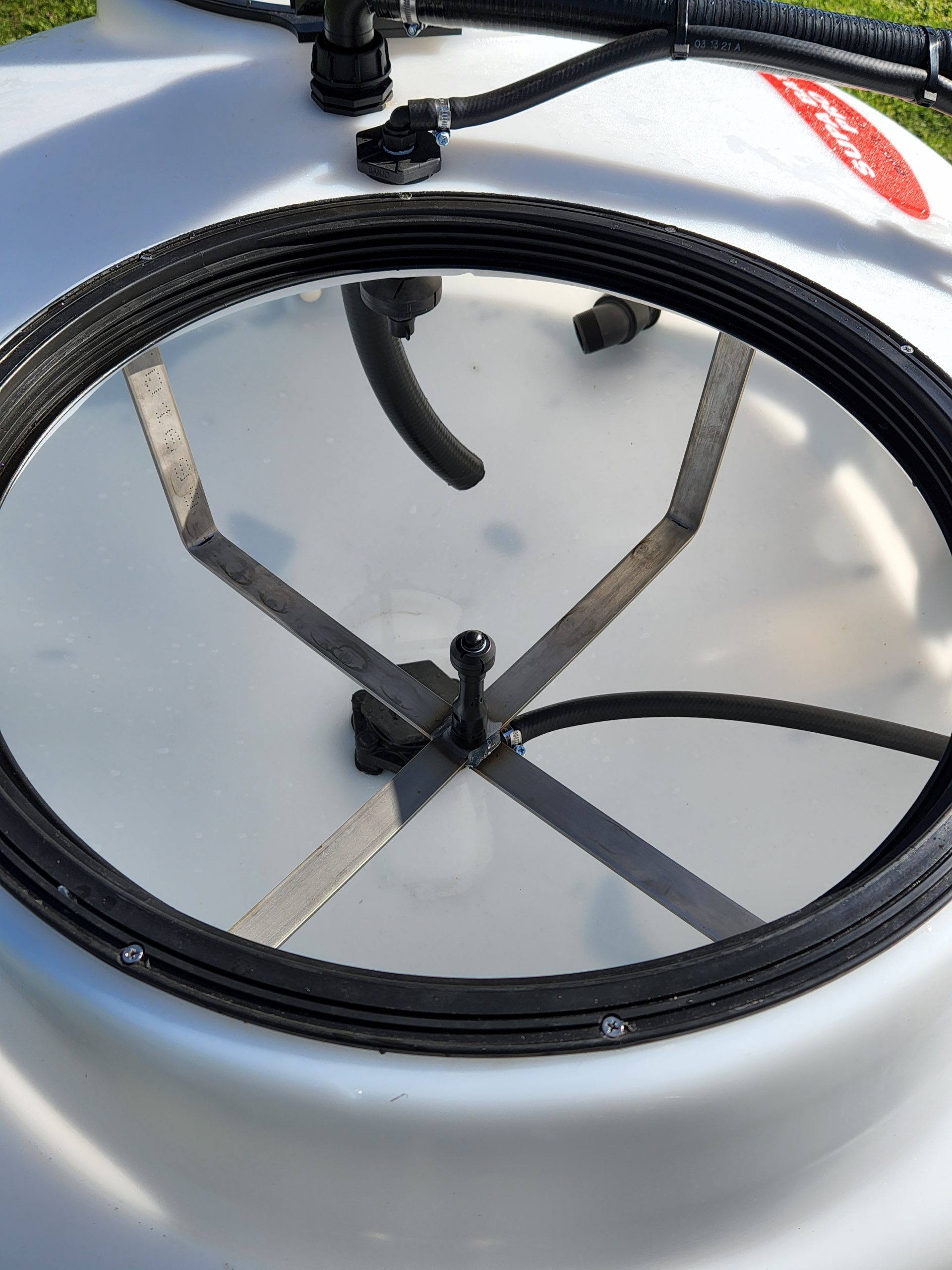

Our Supa Batch Pros come with a cone shaped floor that allows for optimum flow around the tank. In addition to these elements, our system includes dual 2” agitation ports which complete the mixing operation.

With a bag buster knife and drum rinse as standard features.

The 3” Banjo pump with 6.5HP Honda engine delivers rapid mixing and agitation.

Fitted with high flow venturi for liquid chemical induction with 3 individual ports for different chemical inlet suction options.

Solid Galvanised frame base with forklift points for ease of movement when & where required.

The Supa BatchPro is fitted with a complete fresh water flushing system which allows the tank to be fully flushed with fresh water for cleanout and decontamination. Alternatively, this freshwater pump can be used for fresh water supply into your sprayer whilst the chemicals are mixing with the first pump, saving sprayer fill time and less engine hours on self-propelled sprayers and tractors

KEY FEATURES

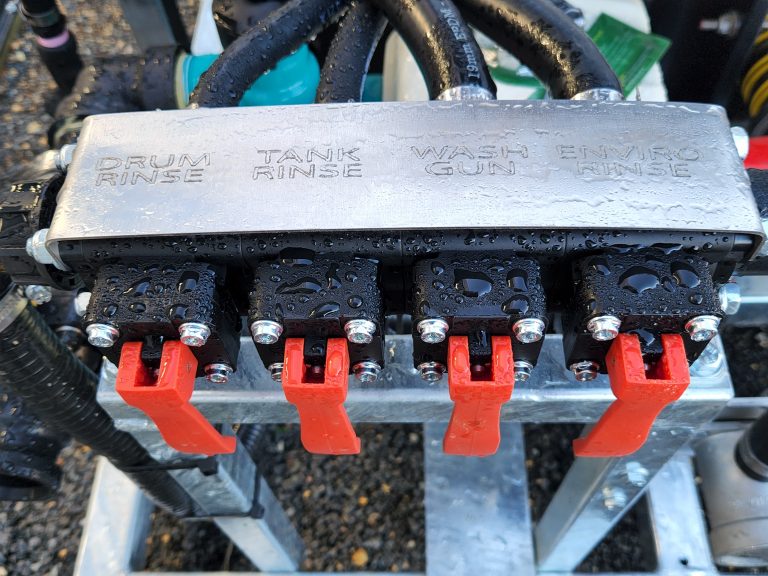

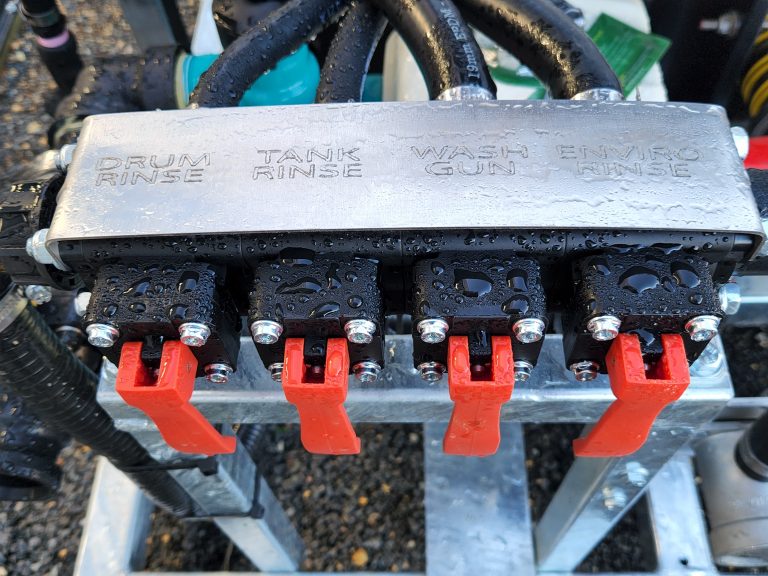

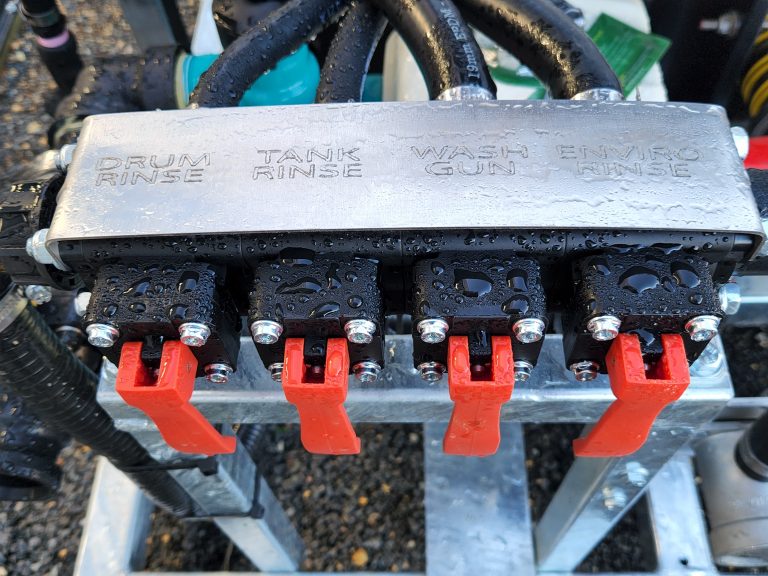

- Bag/drum knife for ease of bulk unloading of chemical drums and bags

- Drum Rinse

- Tank Rinse

- Wash down gun

- Enviro cleanout

SAVINGS

- Reduced depreciation of the sprayer (engine hours)

- Lower fuel costs

- Faster fill and mixing times

- Improved chemical mix quality

- Can have your next batch mixed and ready to go whilst out spraying

MIXING AND TRANSFER

Put safety to the top of the list with Croplands purpose-built chemical handling solutions.

Our chemical handling equipment ensures the safe and efficient transfer and mixing of chemicals when preparing to spray.

CHEMPAK CHEMICAL MIXERS

ChemPak 30 Litre

ChemPak 60 Litre with Stand

ChemPak 60 Litre

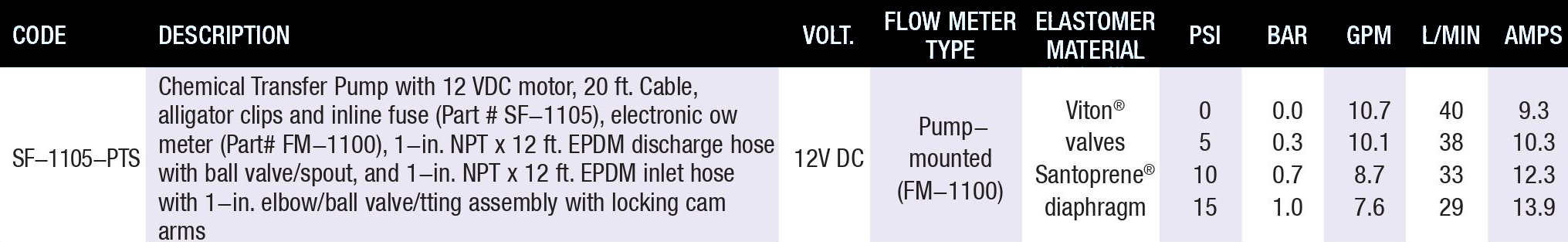

If you are loading a sprayer, Dura Products through Croplands has a solution for you

Dura Products provides a variety of chemical mixing and loading solutions that fit your needs.

Choosing a Dura Product solution is essential for successful delivery of chemicals.

Understanding your requirements and compatibility is crucial before making a selection.

KEY FEATURES

- Highly-efficient design delivers increased flow with viscous microencapsulated or suspended chemicals

- High flow rate while pumping viscous chemicals, in combination with free-flowing return loop, provides substantially increased turnover rate on recirculation models

- SHURflo proprietary designed co-molded diaphragm molecularly bonds the pump piston to the diaphragm in the molding process. The result is an inherently leakproof diaphragm capable of years of trouble-free service

- The highly efficient design utilizes a SHURflo-built 3” diameter permanent magnet motor— more performance and less weight, without more cost

With a 800lt capacity tank and cone shaped floor that allows for optimum flow around the tank. In addition to these elements, our system includes dual 2” agitation ports which complete the mixing operation.

With a bag buster knife and drum rinse as standard features.

The 3” Banjo pump with 6.5HP Honda engine delivers rapid mixing and agitation.

Fitted with high flow venturi for liquid chemical induction with 3 individual ports for different chemical inlet suction options.

Solid Galvanised frame base with forklift points for ease of movement when & where required.

The Supa BatchPro is fitted with a complete fresh water flushing system which allows the tank to be fully flushed with fresh water for cleanout and decontamination. Alternatively, this freshwater pump can be used for fresh water supply into your sprayer whilst the chemicals are mixing with the first pump, saving sprayer fill time and less engine hours on self-propelled sprayers and tractors

Key Features

- Bag/drum knife for ease of bulk unloading of chemical drums and bags

- Drum Rinse

- Tank Rinse

- Wash down gun

- 3 Way venturi suction system

- Enviro cleanout

Savings

- Reduced depreciation of the sprayer (engine hours)

- Lower fuel costs

- Faster fill and mixing times

- Improved chemical mix quality

- Can have your next batch mixed and ready to go whilst out spraying